The house of quality is a structured approach to product design that ensures customer needs and preferences drive innovation from the earliest stages. By aligning marketing, design, and manufacturing teams, QFD enhances product performance, reduces costly redesigns, and strengthens competitive positioning in the market. This means that marketing, design, and manufacturing teams need to collaborate closely from the earliest stages of product development.1 QFD was first developed in 1972 at Mitsubishi’s Kobe shipyard site and later expanded upon by Toyota and its suppliers. It became widely used in the 1970s in Japan for product and service development.2

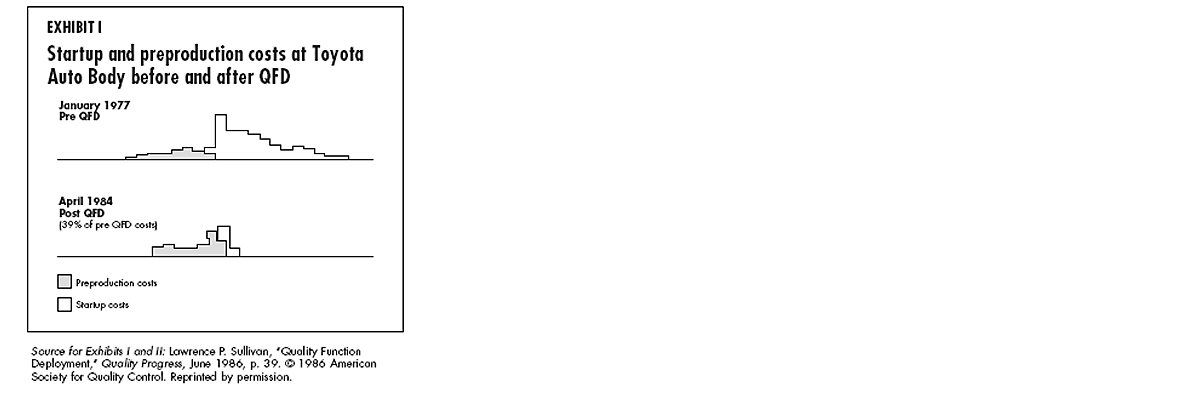

Designing products that satisfy all consumer quality expectations can be challenging due to cost constraints, production limitations, and the need to balance competing consumer demands with engineering feasibility. Strategic quality management involves not just avoiding repairs but also learning from customer feedback and finding a balance between consumer demands and engineering capabilities. The implementation of Quality Function Deployment (QFD) can also lead to cost reduction. For instance, Toyota Auto Body witnessed a significant drop in startup and preproduction costs after implementing QFD in 1984 compared to the costs incurred in 1977 before its adoption. The use of House of Quality meetings during the initial phases led to a cost reduction of over 60%. 3 4

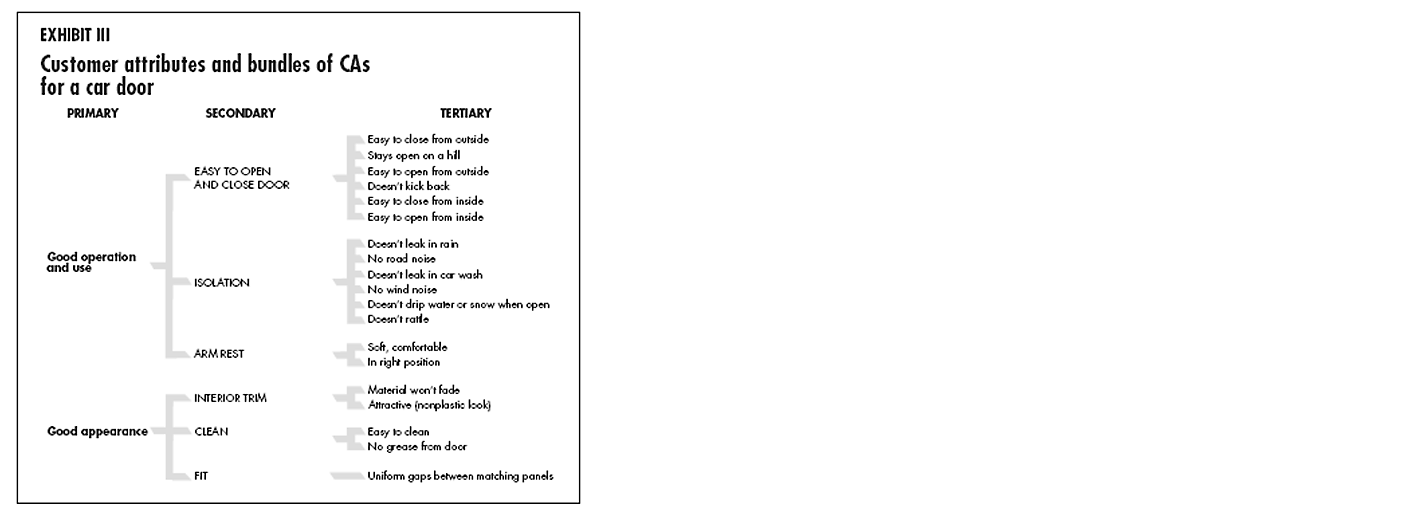

The House of Quality starts with the customer, whose requirements are known as Customer Attributes (CAs). These are phrases that customers use to describe products and their characteristics. Typically, a single application will have 30 to 100 CAs, which are often grouped into bundles of attributes that represent an overall customer concern, such as “open-close” or “isolation”. CAs are generally reproduced in the customers’ own words, and experienced users of the house of quality try to preserve customers’ phrases and even clichés. CAs can include the demands of regulators (“safe in a side collision”), the needs of retailers (“easy to display”), the requirements of vendors (“satisfy assembly and service organizations”), and so on.5 6 7 8

When it comes to designing, designers often have to make a trade-off between different benefits. The house of quality measures the importance of customer’s preferences and weighs them based on team members’ experience with customers or surveys. Some businesses use statistical techniques to determine customer preferences for existing or hypothetical products. Other companies use “revealed preference techniques” to understand customer tastes through their actions and words. The weightings are displayed next to each customer attribute (CA) in percentages, with a complete list totaling 100%.9 10

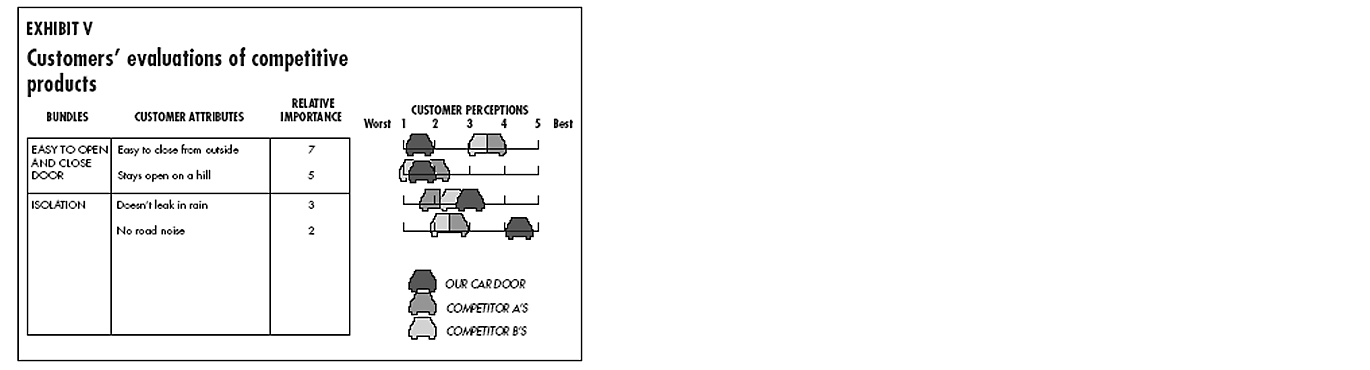

Meeting perceived customer needs can provide a company with a competitive edge by aligning product design with market expectations and strategic positioning. To achieve this, companies must first understand where they stand compared to their competition. In the right section of the diagram, opposite the Competitive Attributes (CAs), we list customer evaluations of competitor cars compared to our own. This comparison helps identify areas for improvement and is known as a “perceptual map” in marketing. Bundles of CAs are often used to strategically position a product or product line. This section of the house of quality creates a natural connection between product concepts and a company’s strategic vision.11 12

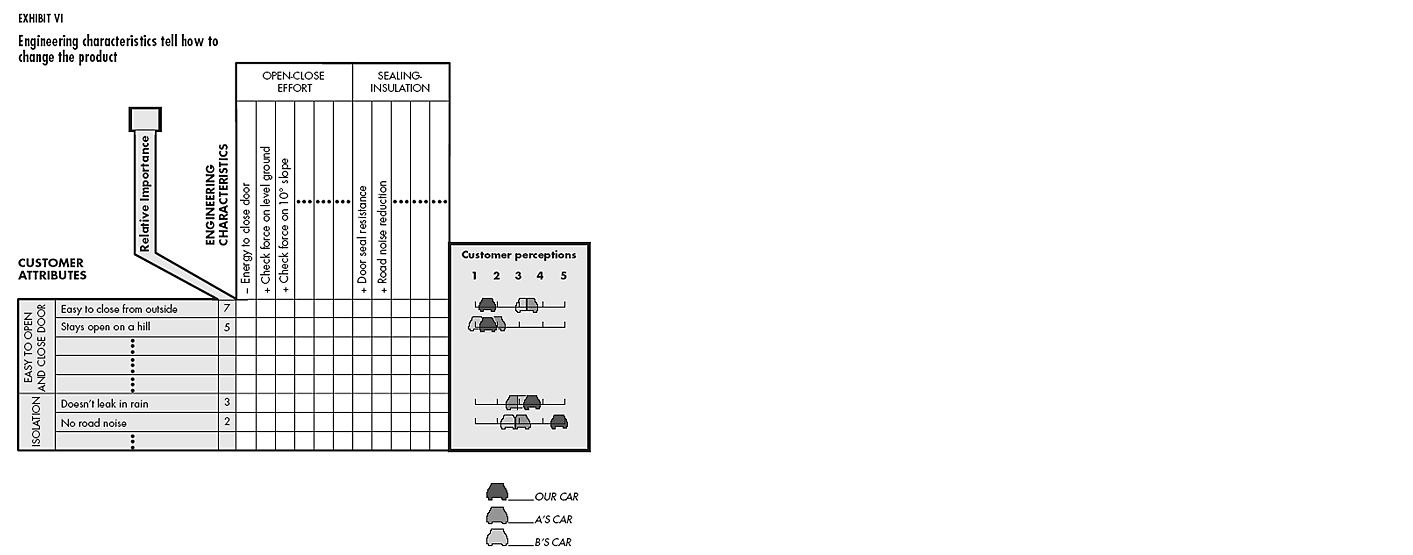

How can we modify the product? The marketing department tells us what needs to be done, while the engineering department provides us with the means to do it. Now, we must describe the product in a language that engineers can understand. Using the house of quality, the design team lists engineering characteristics (ECs) that could impact one or more customer attributes. The negative sign next to “energy to close door” signifies that engineers aim to reduce the amount of energy required. If a standard engineering characteristic does not affect any customer attribute, it may be unnecessary to include it on the EC list or the design team may have overlooked a customer attribute. Conversely, if a customer attribute is unaffected by any EC, it presents an opportunity to enhance the physical properties of the car.13

It is possible for an EC to impact multiple CAs. To accurately describe a product, engineering characteristics should be measurable and directly impact customer perception. In Japanese projects, inter-functional teams start with CAs and determine quantifiable characteristics for each, such as the amount of energy needed to close a door. This is a crucial phase for thorough and thoughtful analysis of each characteristic and brainstorming. Unclear or vague characteristics will ultimately lead to disinterest in customer needs. Trivial characteristics can distract the team from the bigger picture and hinder creativity.14 15

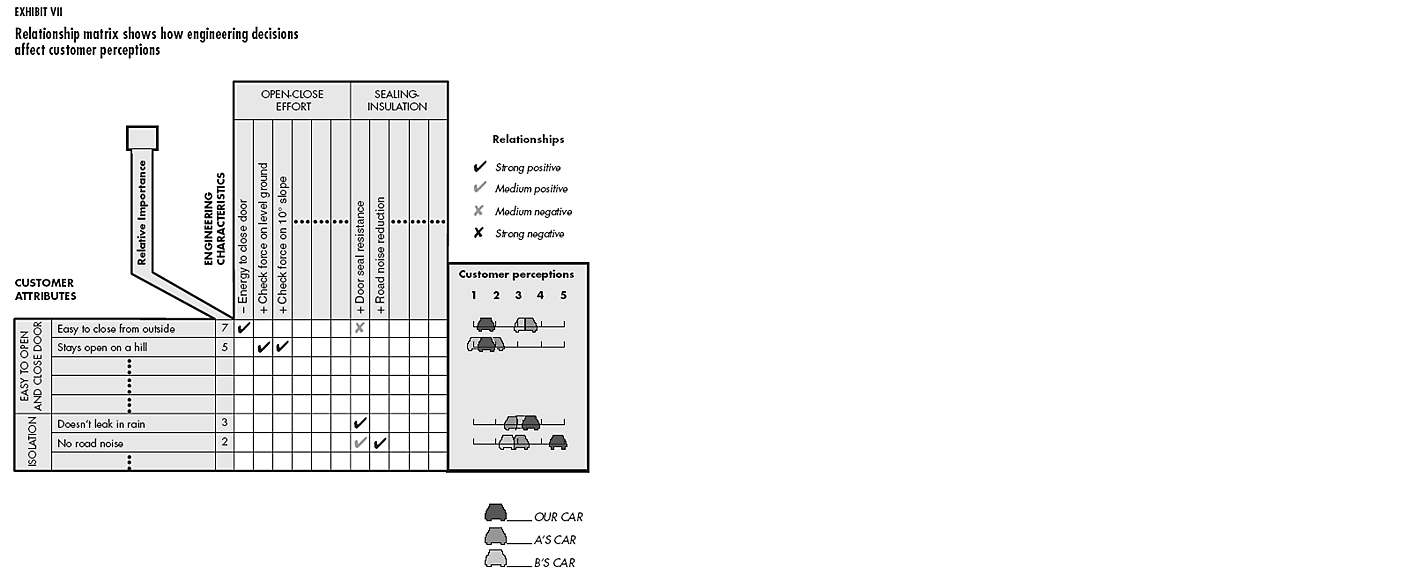

To what extent do engineers impact customers’ perception of product quality? The team responsible for cross-functional collaboration is now completing the “relationship matrix”, which illustrates the degree to which each engineering feature affects each customer attribute. The team will use numerical values or symbols to indicate the strength of these connections.16 17

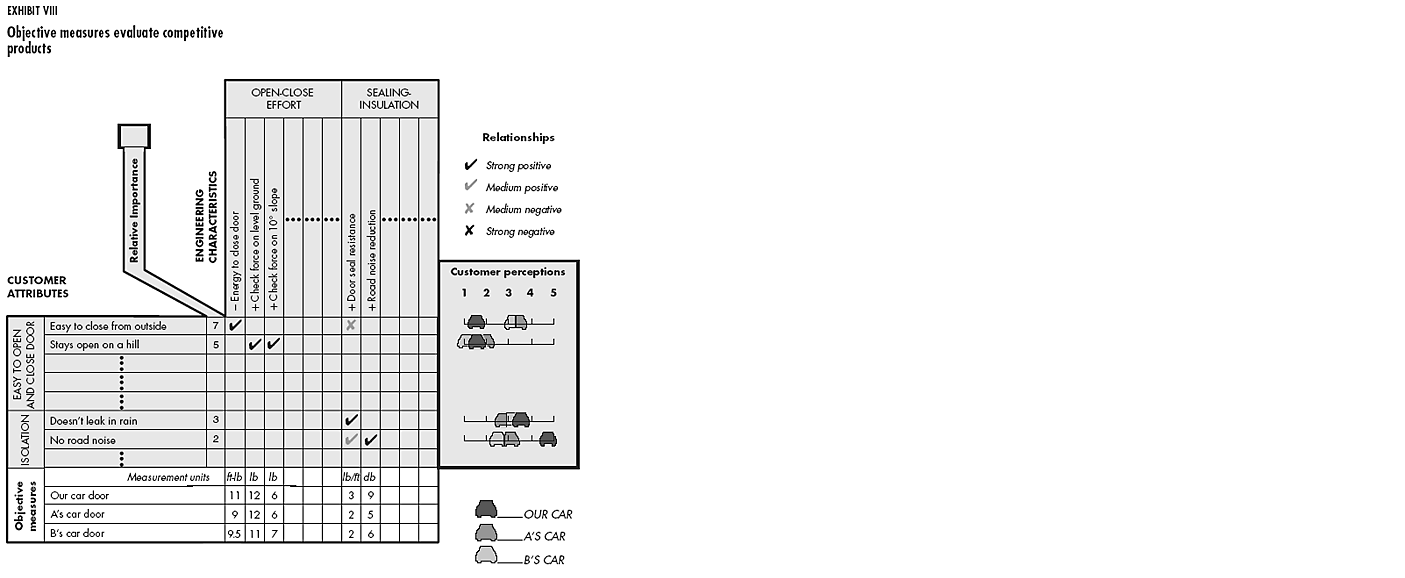

After identifying the voice of the customer and linking it to engineering characteristics, the team adds objective measures at the bottom of the house, corresponding to the ECs. With known objective measures, the team can establish target values for each EC in a redesigned product. If the team properly identified the ECs, completing tests to measure benchmark values should be easy. Engineers determine the relevant units of measurement such as foot pounds, decibels, etc.18

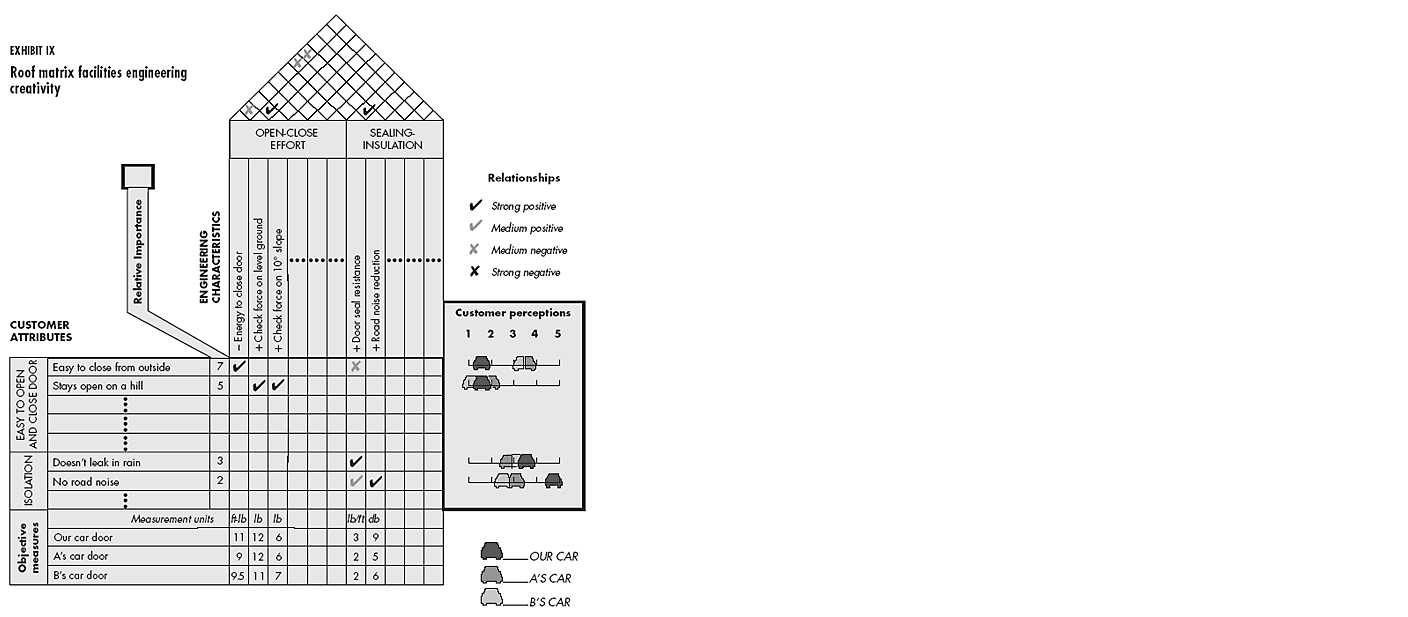

When making changes to engineering features, it’s important to consider how they will affect other characteristics. For example, reducing the weight of a car door to enhance fuel efficiency might inadvertently increase road noise or reduce impact resistance. Engineers must carefully evaluate these trade-offs to ensure that improvements in one area do not compromise overall product quality. The house of quality’s roof matrix is a helpful tool that allows engineers to specify the necessary improvements in a way that maintains the balance between different features. In some cases, a change to one feature may negatively impact others, leading the team to decide to leave it as is. The roof matrix also makes it easier to make necessary trade-offs between different engineering features. This tool is critical for engineers to use as they strive to balance customer benefits with technical requirements.19 20

“(…) the roof contains the most critical information for engineers because they use it to balance the trade-offs when addressing customer benefits.”

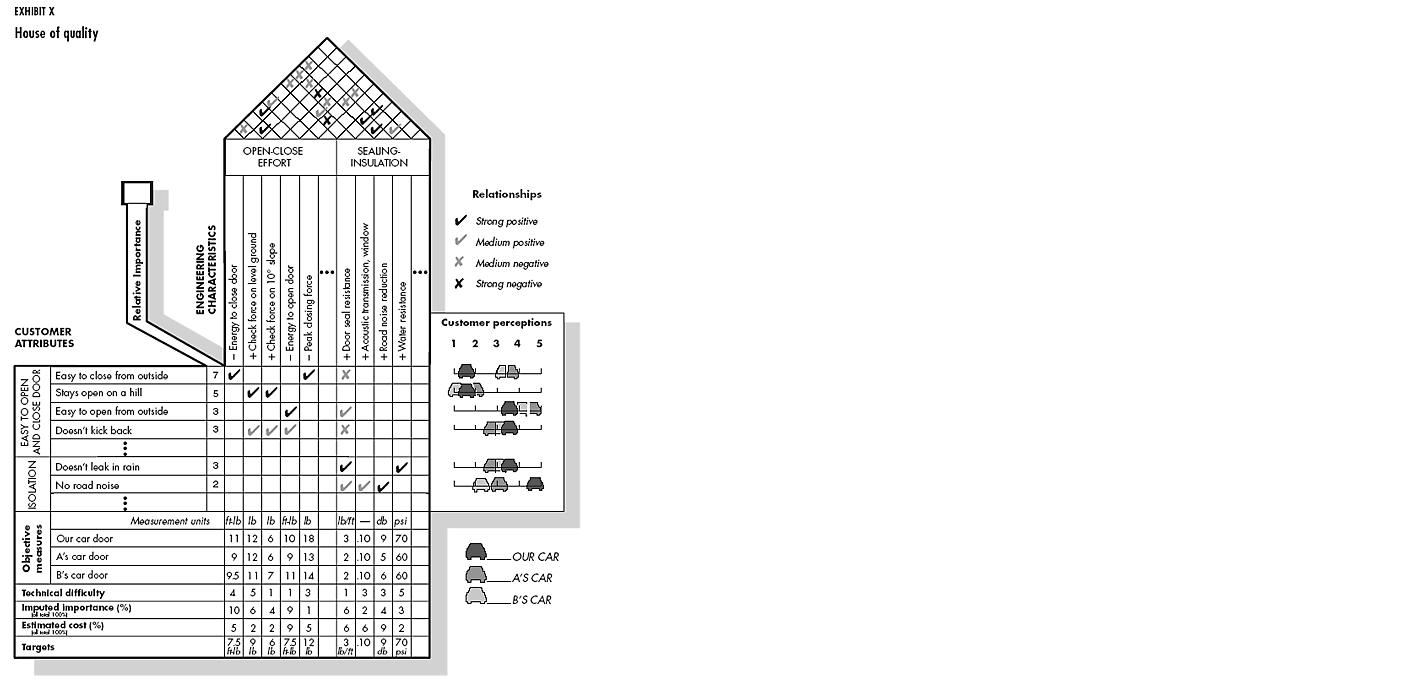

Design teams often prefer to consider additional information when custom-building houses. They might add columns to the list of CAs for customer complaint histories and to the ECs for the costs of servicing these complaints. Some applications also include data from the sales force in the CA list to reflect strategic marketing decisions. Engineers may even add a row indicating the level of technical difficulty involved in making a change. Some users assign relative weights to engineering characteristics, which can be compared to actual component costs. By doing so, creative design teams can prioritize improvements to components. This information is especially valuable when cost-cutting is a goal.21 22

The house of quality contributes to the bottom line by improving cross-functional collaboration, reducing redesign costs, and enhancing customer satisfaction. By integrating customer needs with engineering capabilities, companies can optimize product development efficiency, minimize production waste, and accelerate time-to-market, ultimately increasing profitability. Although there is no standardized method, the house aids teams in setting objectives that ultimately impact the bottom line. Engineers utilize it to condense essential information into manageable formats, while marketing executives rely on it to represent the customer’s opinion. General managers can use it to identify strategic prospects.

Overall, the house promotes collaboration among these groups to enhance comprehension of each other’s priorities and objectives.23

Footnotes

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “The foundation of the house of quality is the belief that products should be designed to reflect customers’ desires and tastes—so marketing people, design engineers, and manufacturing staff must work closely together from the time a product is first conceived.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “The “house of quality,” the basic design tool of the management approach known as quality function deployment (QFD), originated in 1972 at Mitsubishi’s Kobe shipyard site. Toyota and its suppliers then developed it in numerous ways. The house of quality has been used successfully by Japanese manufacturers of consumer electronics, home appliances, clothing, integrated circuits, synthetic rubber, construction equipment, and agricultural engines. Japanese designers use it for services like swimming schools and retail outlets and even for planning apartment layouts.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “David Garvin points out that there are many dimensions to what a consumer means by quality and that it is a major challenge to design products that satisfy all of these at once. Strategic quality management means more than avoiding repairs for consumers. It means that companies learn from customer experience and reconcile what they want with what engineers can reasonably build.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Exhibit I compares startup and preproduction costs at Toyota Auto Body in 1977, before QFD, to those costs in 1984, when QFD was well under way. House of quality meetings early on reduced costs by more than 60%. Exhibit II reinforces this evidence by comparing the number of design changes at a Japanese auto manufacturer using QFD with changes at a U.S. automaker. The Japanese design was essentially frozen before the first car came off the assembly line, while the U.S. company was still revamping months later.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “What do customers want? The house of quality begins with the customer, whose requirements are called customer attributes (CAs)—phrases customers use to describe products and product characteristics (see Exhibit III). We’ve listed a few here; a typical application would have 30 to 100 CAs. A car door is “easy to close” or “stays open on a hill”; “doesn’t leak in rain” or allows “no (or little) road noise.” Some Japanese companies simply place their products in public areas and encourage potential customers to examine them, while design team members listen and note what people say. Usually, however, more formal market research is called for, via focus groups, in-depth qualitative interviews, and other techniques.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “CAs are often grouped into bundles of attributes that represent an overall customer concern, like “open-close” or “isolation.” The Toyota rust-prevention study used eight levels of bundles to get from the total car down to the car body. Usually the project team groups CAs by consensus, but some companies are experimenting with state-of-the-art research techniques that derive groupings directly from customers’ responses (and thus avoid arguments in team meetings).” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “CAs are generally reproduced in the customers’ own words. Experienced users of the house of quality try to preserve customers’ phrases and even clichés—knowing that they will be translated simultaneously by product planners, design engineers, manufacturing engineers, and salespeople. Of course, this raises the problem of interpretation: What does a customer really mean by “quiet” or “easy”? Still, designers’ words and inferences may correspond even less to customers’ actual views and can therefore mislead teams into tackling problems customers consider unimportant.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Not all customers are end users, by the way. CAs can include the demands of regulators (“safe in a side collision”), the needs of retailers (“easy to display”), the requirements of vendors (“satisfy assembly and service organizations”), and so forth.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Are all preferences equally important? Imagine a good door, one that is easy to close and has power windows that operate quickly. There is a problem, however. Rapid operation calls for a bigger motor, which makes the door heavier and, possibly, harder to close. Sometimes a creative solution can be found that satisfies all needs. Usually, however, designers have to trade off one benefit against another.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “To bring the customer’s voice to such deliberations, house of quality measures the relative importance to the customer of all CAs. Weightings are based on team members’ direct experience with customers or on surveys. Some innovative businesses are using statistical techniques that allow customers to state their preferences with respect to existing and hypothetical products. Other companies use “revealed preference techniques,” which judge consumer tastes by their actions as well as by their words—an approach that is more expensive and difficult to perform but yields more accurate answers. (Consumers say that avoiding sugar in cereals is important, but do their actions reflect their claims?)” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “_Will delivering perceived needs yield a competitive advantage?_Companies that want to match or exceed their competition must first know where they stand relative to it. So on the right side of the house, opposite the CAs, we list customer evaluations of competitive cars matched to “our own” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Marketing professionals will recognize the right-hand side of _Exhibit V_as a “perceptual map.” Perceptual maps based on bundles of CAs are often used to identify strategic positioning of a product or product line. This section of the house of quality provides a natural link from product concept to a company’s strategic vision.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “How can we change the product? The marketing domain tells us what to do, the engineering domain tells us how to do it. Now we need to describe the product in the language of the engineer. Along the top of the house of quality, the design team lists those engineering characteristics (ECs) that are likely to affect one or more of the customer attributes (see Exhibit VI). The negative sign on “energy to close door” means engineers hope to reduce the energy required. If a standard engineering characteristic affects no CA, it may be redundant to the EC list on the house, or the team may have missed a customer attribute. A CA unaffected by any EC, on the other hand, presents opportunities to expand a car’s physical properties.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Engineering characteristics should describe the product in measurable terms and should directly affect customer perceptions. The weight of the door will be felt by the customer and is therefore a relevant EC. By contrast, the thickness of the sheet metal is a part characteristic that the customer is unlikely to perceive directly. It affects customers only by influencing the weight of the door and other engineering characteristics, like “resistance to deformation in a crash.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “In many Japanese projects, the interfunctional team begins with the CAs and generates measurable characteristics for each, like foot-pounds of energy required to close the door. Teams should avoid ambiguity in interpretation of ECs or hasty justification of current quality control measurement practices. This is a time for systematic, patient analysis of each characteristic, for brainstorming. Vagueness will eventually yield indifference to things customers need. Characteristics that are trivial will make the team lose sight of the overall design and stifle creativity.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “How much do engineers influence customer-perceived qualities? The interfunctional team now fills in the body of the house, the “relationship matrix,” indicating how much each engineering characteristic affects each customer attribute. The team seeks consensus on these evaluations, basing them on expert engineering experience, customer responses, and tabulated data from statistical studies or controlled experiments.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “The team uses numbers or symbols to establish the strength of these relationships (see Exhibit VII). Any symbols will do; the idea is to choose those that work best. Some teams use red symbols for relationships based on experiments and statistics and pencil marks for relationships based on judgment or intuition. Others use numbers from statistical studies. In our house, we use check marks for positive and crosses for negative relationships.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Once the team has identified the voice of the customer and linked it to engineering characteristics, it adds objective measures at the bottom of the house beneath the ECs to which they pertain (see Exhibit VIII). When objective measures are known, the team can eventually move to establish target values—ideal new measures for each EC in a redesigned product. If the team did its homework when it first identified the ECs, tests to measure benchmark values should be easy to complete. Engineers determine the relevant units of measurement—foot-pounds, decibels, etc.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “How does one engineering change affect other characteristics? An engineer’s change of the gear ratio on a car window may make the window motor smaller but the window go up more slowly. And if the engineer enlarges or strengthens the mechanism, the door probably will be heavier, harder to open, or may be less prone to remain open on a slope. Of course, there might be an entirely new mechanism that improves all relevant CAs. Engineering is creative solutions and a balancing of objectives.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Sometimes one targeted feature impairs so many others that the team decides to leave it alone. The roof matrix also facilitates necessary engineering trade-offs. The foot-pounds of energy needed to close the door, for example, are shown in negative relation to “door seal resistance” and “road noise reduction.” In many ways, the roof contains the most critical information for engineers because they use it to balance the trade-offs when addressing customer benefits.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Incidentally, we have been talking so far about the basics, but design teams often want to ruminate on other information. In other words, they custom-build their houses. To the column of CAs, teams may add other columns for histories of customer complaints. To the ECs, a team may add the costs of servicing these complaints. Some applications add data from the sales force to the CA list to represent strategic marketing decisions. Or engineers may add a row that indicates the degree of technical difficulty, showing in their own terms how hard or easy it is to make a change.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “Some users of the house impute relative weights to the engineering characteristics. They’ll establish that the energy needed to close the door is roughly twice as important to consider as, say, “check force on 10° slope.” By comparing weighted characteristics to actual component costs, creative design teams set priorities for improving components. Such information is particularly important when cost cutting is a goal.” ↩

-

Hauser, J.R., Clausing, D., 1988. The House of Quality. Harvard Business Review. URL (accessed 7.7.23). “How does the house lead to the bottom line? There is no cookbook procedure, but the house helps the team to set targets, which are, in fact, entered on bottom line of the house. For engineers it is a way to summarize basic data in usable form. For marketing executives it represents the customer’s voice. General managers use it to discover strategic opportunities. Indeed, the house encourages all of these groups to work together to understand one another’s priorities and goals.” ↩