Quality Function Deployment (QFD) was the foundation of our product development process, ensuring that every engineering decision was directly tied to market demands. The method was structured to extract customer priorities from real-world data and translate them into quantifiable product attributes.

The process began with a structured data collection phase. Instead of relying on subjective assumptions or small-scale surveys, we analyzed 295 customer reviews from competitors like Ooni, DeliVita, and Morsø. This approach provided an unfiltered view of user pain points and preferences. The data was systematically classified into Customer Attributes (CAs), critical product features users explicitly or implicitly valued. Heat control, cooking performance, usability, and material durability were identified as top priorities, while common complaints included thermal inefficiencies, slow preheating times, and difficulties in temperature regulation.

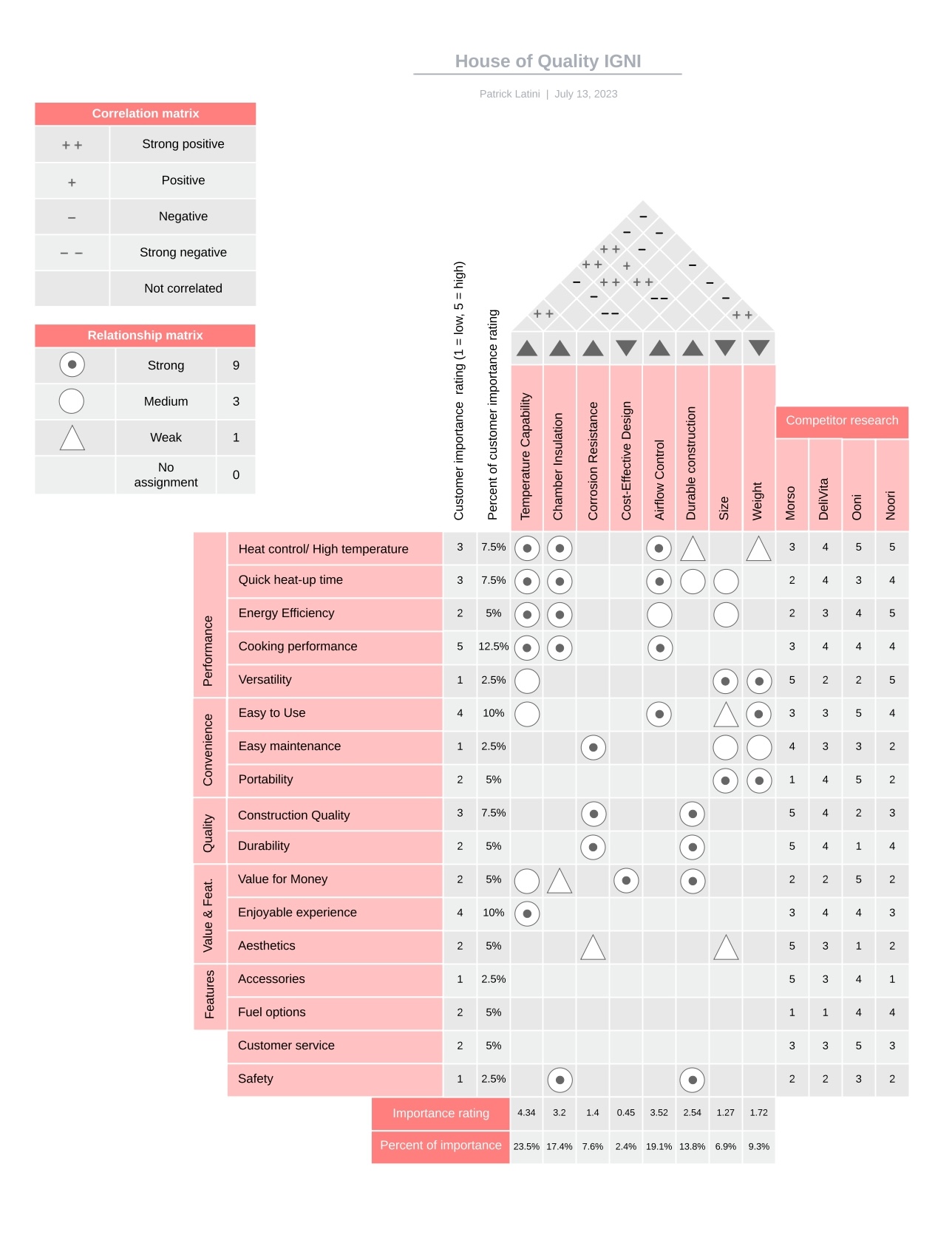

From this, a House of Quality matrix was built, mapping each customer attribute to engineering specifications. Key performance indicators, such as temperature range (425 - 480°C), thermal insulation efficiency (target < 0.7 W/mK), and airflow optimization metrics were established. These specifications were benchmarked against competitors, ensuring our product would meet or exceed industry standards while maintaining cost efficiency.

The engineering team then performed a trade-off analysis using the QFD framework’s roof matrix, identifying interactions between different design choices. This process eliminated redundant features while reinforcing critical elements that had a direct impact on customer satisfaction. Airflow control, for example, was refined to enhance both grilling efficiency and even heat distribution for pizza baking, addressing a key market gap.

By integrating statistical weighting into the QFD matrix, we ensured that the most critical product characteristics received priority in design execution. The final engineering characteristics ranking was directly aligned with customer-derived insights, eliminating unnecessary complexity and optimizing resource allocation for manufacturing.

The structured implementation of QFD reduced design iteration cycles, minimized late-stage modifications, and ensured a market-validated product development path. This approach provided a clear competitive advantage, positioning the product with features explicitly demanded by the target market while maintaining cost-effective manufacturability.

The structured implementation of QFD reduced design iteration cycles, minimized late-stage modifications, and ensured a market-validated product development path. This approach provided a clear competitive advantage, positioning the product with features explicitly demanded by the target market while maintaining cost-effective manufacturability.